A Design team with rich field experience and advanced manufacturing equipment make mold designing and new product development fast, meeting the ever changing demand of customers

- + Design staff: 15 staff

- + Average years of experience: 8-9 years

- + Staff of handling, fixing, maintaining mold: 150 staff

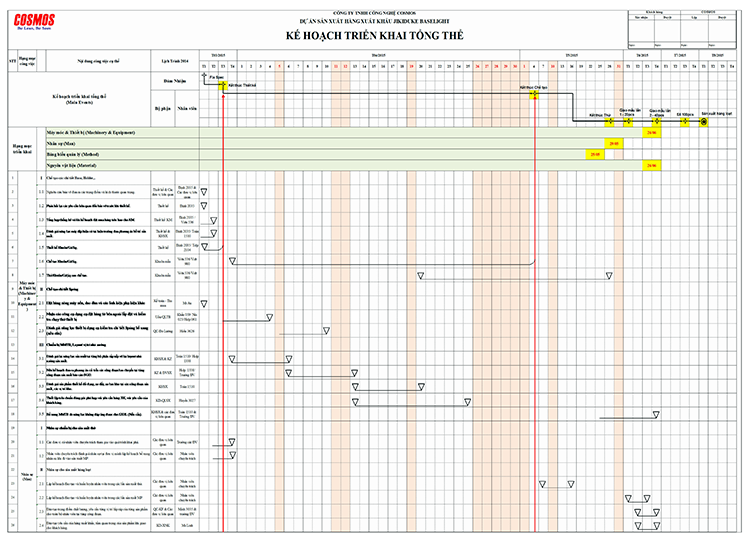

The product development plan is managed according to customer's master schedule through professional management tools and processes. Mold design plan is specific for each mold, ensuring that every tiny problem is resolved and does not affect the general plan.

Advanced machines and technology help COSMOS shorten exploration process with sustainable quality and precision. Exploration time for a product may vary from 3 days to 2 months subjecting to the complexity of products.

- + Using Laser cutting machine to cut profile helps shorten mold manufacturing time.

- + Line cutting machine Seibu (Japan) can shear with high precision and work 24/24 with the function of automatic reeving.

- + Various kinds of CNC handling equipment and other tools.

Please refer to Molding equipment

(84) 211-372-1138

(84) 211-372-1138  (84) 211-384-7877

(84) 211-384-7877